- This topic is empty.

-

AuthorPosts

-

10/11/2025 at 15:13 #6505

In the building materials industry, equipment such as crushers, mills, conveyors, and dust collectors operates under harsh conditions. They are frequently exposed to abrasive materials like limestone, clinker, gypsum, and coal ash, leading to severe surface wear and tear. As a result, the maintenance cost of production lines is high, and frequent downtime affects productivity.

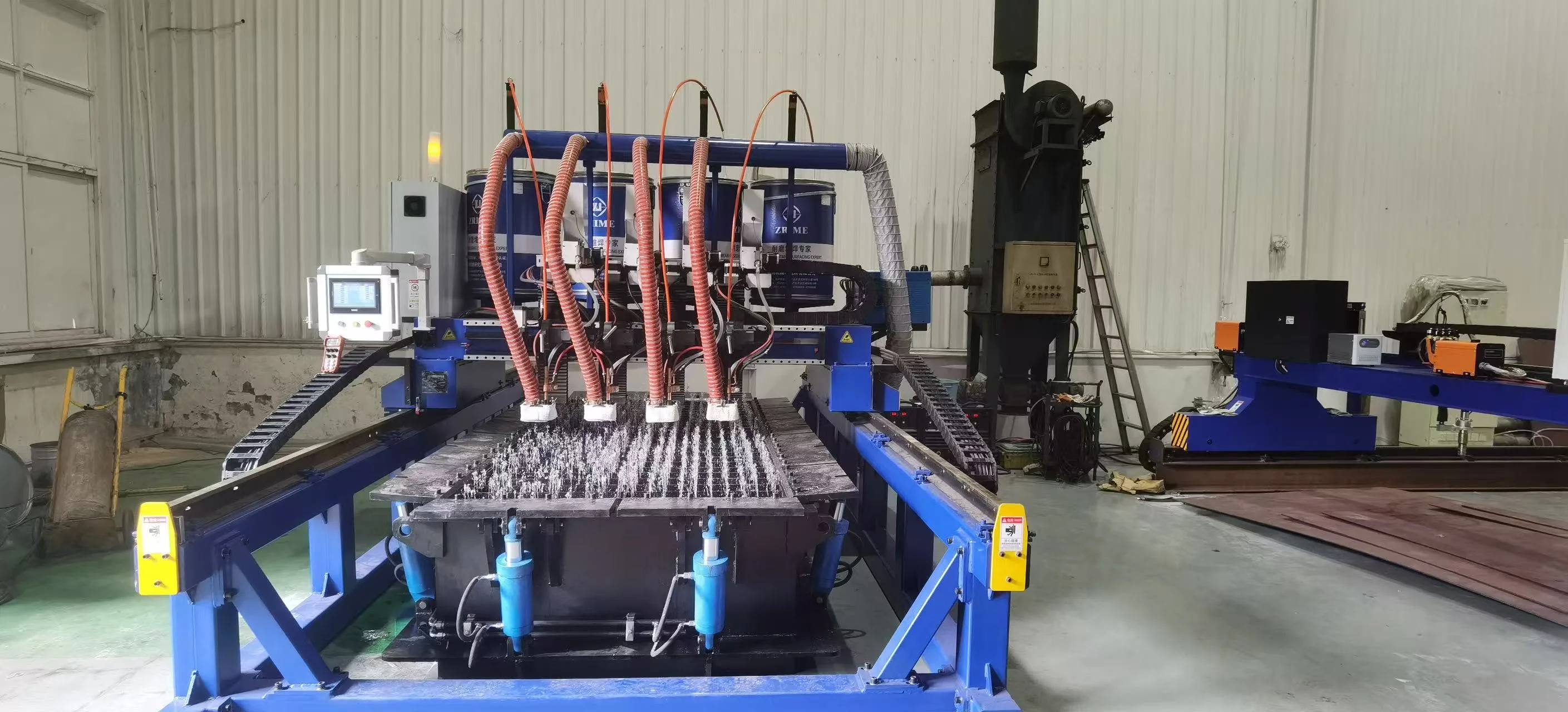

To address this issue, wear-resistant plate surfacing welding machines have become an essential solution. This equipment allows manufacturers to apply a durable hardfacing layer on ordinary steel plates, transforming them into wear-resistant plates with excellent hardness, toughness, and corrosion resistance. The technology effectively extends the service life of building material equipment and reduces maintenance frequency and costs.

1. Overview of Wear-Resistant Plate Surfacing Welding Machines

A wear-resistant plate surfacing welding machine is a specialized welding system designed to create composite plates with a hard, wear-resistant surface layer. The process involves welding a layer of wear-resistant alloy (typically chromium carbide, tungsten carbide, or nickel-based alloys) onto a mild steel substrate.

Key Components

-

Welding Head and Torch System – Delivers the hardfacing alloy via an electric arc or plasma process.

-

Automatic Control System – PLC or CNC system ensures consistent welding path, uniform layer thickness, and reduced human error.

-

Worktable and Fixture – Holds steel plates securely, minimizing thermal deformation during welding.

-

Cooling System – Air or water-cooled systems that prevent overheating and preserve plate flatness.

-

Wire Feeding Mechanism – Ensures steady material feed for continuous overlay welding.

This machine integrates automatic motion control, precise temperature management, and multi-layer welding capability, making it ideal for mass production of wear-resistant plates used in heavy-duty industries such as cement and construction materials.

2. Importance in the Building Materials Industry

The building materials sector—especially cement plants, concrete batching facilities, and aggregate production lines—deals with materials that cause intense friction and impact. Conventional carbon steel components often wear out rapidly, leading to costly replacements.

By adopting wear-resistant plate surfacing welding technology, building materials manufacturers can:

-

Improve component durability – Hardfaced surfaces offer 5–10 times higher wear resistance than ordinary steel.

-

Reduce downtime – Longer component life minimizes shutdowns and production interruptions.

-

Enhance cost efficiency – Refurbishing or manufacturing wear plates in-house lowers material and labor costs.

-

Ensure stable product quality – Consistent equipment performance guarantees uniform cement fineness and output.

3. Typical Applications in the Building Materials Industry

(1) Cement Manufacturing

Cement production is one of the most demanding environments for wear-resistant technology. From raw material crushing to clinker grinding, every process involves high-speed contact with abrasive particles.

Key Applications:

-

Crusher Liners and Hammers: Jaw crushers, cone crushers, and impact crushers suffer severe wear. Surfaced wear plates can protect impact areas and extend their lifetime significantly.

-

Raw Mill and Coal Mill Shells: Surfacing welding helps maintain the internal lining’s thickness, reducing replacement frequency.

-

Separator Blades and Duct Elbows: Surfaced components prevent material erosion and air leakage due to abrasion.

-

Conveyor and Bucket Elevator Housings: Continuous material flow causes sliding wear. Surfaced plates reduce friction and energy consumption.

In cement plants, using wear-resistant plate surfacing welding machines enables on-site fabrication of liners and wear plates, allowing maintenance teams to produce customized components quickly and economically.

(2) Aggregate and Concrete Production

In sand and gravel plants, materials such as granite and basalt continuously erode equipment surfaces.

Surfaced plates are applied to:-

Hopper Liners

-

Chute and Screen Decks

-

Mixing Drum Interiors

The hardfacing layer prevents direct metal-to-rock contact, maintaining the geometry of equipment and ensuring stable mixing and screening efficiency.

(3) Gypsum and Lime Processing

These industries involve handling fine powders that create not only abrasion but also corrosion from alkaline or acidic compounds. The surfacing welding machine allows the application of chromium-nickel or chromium-molybdenum alloys, which resist both wear and chemical attack.

Typical uses include:

-

Screw Conveyor Flights

-

Fan Blades and Casing Liners

-

Material Valves and Feeders

(4) Clinker Conveying and Storage Systems

After high-temperature clinker leaves the kiln, it is extremely abrasive and thermally aggressive. Surfaced wear plates made with chromium carbide overlays can withstand both high heat (up to 600 °C) and high abrasion, ideal for:

-

Clinker cooler plates

-

Chain conveyors

-

Clinker crusher walls and chutes

The wear-resistant plate surfacing welding machine ensures these parts are produced with consistent quality and dimensional accuracy, maintaining the plant’s output reliability.

4. Working Principle in Building Materials Equipment

The machine typically uses submerged arc welding (SAW) or open-arc welding to deposit a hardfacing alloy onto the base metal.

-

The steel substrate (e.g., Q235, Q345) is fixed on the worktable.

-

The system feeds flux-cored wire containing chromium carbide or tungsten carbide.

-

A stable arc melts both the filler and part of the substrate to create a metallurgical bond.

-

The overlay solidifies into a high-hardness surface (HRC 55–65).

The resulting bimetal composite plate features a tough base with a hard outer layer, combining strength and wear resistance—perfect for rotating, sliding, and impact conditions found in cement plants.

5. Benefits of Applying Wear-Resistant Surfacing Technology

Aspect Benefit Wear Resistance Hardness up to HRC 65; 5–10× longer service life than ordinary steel Corrosion Resistance Alloy composition resists chemical attack from cement dust and alkaline media Heat Resistance Stable performance under 500–600 °C operating temperatures Mechanical Strength Tough steel substrate resists impact and bending Economical Reduced maintenance, repair, and part replacement costs Customizable Different alloys and thicknesses can be selected for specific conditions Through automatic control, a single wear-resistant plate surfacing welding machine can continuously produce multiple plates, ensuring stable batch quality.

6. Integration with Green and Smart Manufacturing

Modern building material plants are shifting toward intelligent and eco-friendly production. Surfacing welding technology aligns with these goals:

-

Resource Efficiency: Repairing worn parts instead of replacing them reduces steel consumption.

-

Energy Efficiency: Optimized overlay welding minimizes heat input, saving power.

-

Digital Control: CNC systems record welding paths, enabling repeatable production and traceability.

-

Reduced Waste: Extending component life minimizes scrap metal generation.

Thus, wear-resistant plate surfacing welding machines contribute to sustainable manufacturing in the building materials sector.

7. Case Example

A cement manufacturer in Southeast Asia previously replaced mill liners every six months due to severe wear. After installing a dual-head wear-resistant plate surfacing welding machine, they began producing their own hardfaced liners with chromium-carbide overlay.

Results:

-

Liner life increased from 6 months to 2.5 years.

-

Maintenance cost reduced by over 60%.

-

Downtime decreased by 40%, improving annual output stability.

This example demonstrates the tangible benefits of integrating surfacing welding technology into routine maintenance systems.

8. Future Development Trends

With advancements in materials and automation, wear-resistant plate surfacing welding machines are evolving toward:

-

Multi-layer composite surfacing for enhanced heat and corrosion resistance.

-

Laser-assisted and plasma surfacing for precision overlays.

-

Robotic systems enabling fully automated production lines.

-

IoT integration for remote monitoring and predictive maintenance.

In the future, these innovations will allow the building materials industry to operate more efficiently, sustainably, and economically.

Conclusion

In the building materials industry, where equipment endures continuous abrasion, wear-resistant plate surfacing welding machines play an irreplaceable role. They not only extend equipment lifespan but also reduce maintenance costs, improve productivity, and align with sustainable manufacturing principles.

For cement plants, concrete producers, and aggregate suppliers aiming to strengthen competitiveness, adopting surfacing welding technology is a forward-looking investment. By utilizing advanced welding automation, companies can ensure stable quality, optimize resources, and achieve long-term operational efficiency.

If your facility seeks to produce customized wear-resistant plates or refurbish high-wear components, integrating a wear-resistant plate surfacing welding machine is the key to achieving higher durability and lower production costs in today’s demanding industrial landscape.

http://www.jhnm-hardfacing.com

jhnm-hardfacing -

-

AuthorPosts

- You must be logged in to reply to this topic.