- This topic is empty.

-

AuthorPosts

-

23/09/2025 at 15:47 #6250

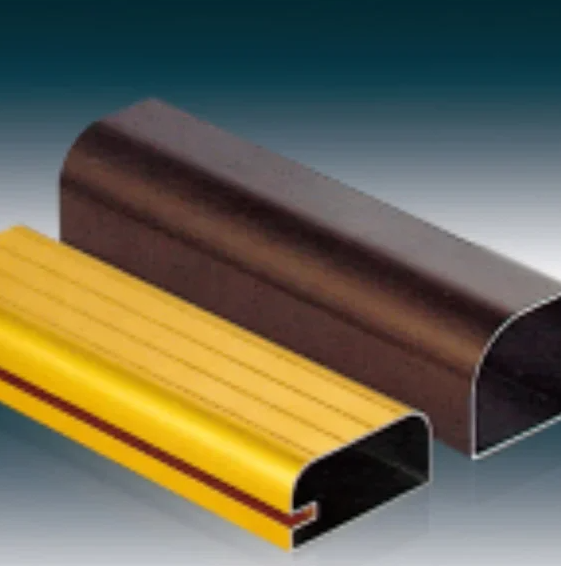

Producing high-quality aluminum profiles requires not only advanced extrusion and coating technologies but also precise mechanical polishing to eliminate surface defects. At KaiMeiDa Aluminum, the largest aluminum production base in Jiangxi Province, we leverage state-of-the-art equipment and expert techniques to deliver high-brightness, corrosion-resistant, and wear-resistant aluminum profiles suitable for a wide range of industrial and architectural applications.

Common Surface Defects in Aluminum

Understanding surface defects is the first step in optimizing aluminum finishing processes.

Scratches, Pits, and Roll Marks

-

Scratches often occur during extrusion or handling.

-

Pits and micro-voids can form due to impurities or inconsistent extrusion.

-

Roll marks result from uneven contact with rollers or improper alignment.

Causes During Extrusion and Coating Preparation

-

Variations in extrusion temperature and speed can create surface irregularities.

-

Improper degreasing or surface preparation before coating may lead to adhesion issues.

-

Even minor inconsistencies in sandblasting or anodic oxidation can amplify surface defects.

Polishing Strategies to Minimize Defects

Effective polishing ensures a uniform surface, preparing aluminum for subsequent treatments.

Stepwise Abrasive Polishing

-

Begin with coarse abrasives to remove major imperfections.

-

Progressively move to finer abrasives for high-brightness finish.

-

Layered polishing reduces risk of over-polishing and preserves profile integrity.

Pressure and Speed Optimization

-

Controlled pressure and rotational speed prevent micro-scratches and heat-induced deformation.

-

Automation and real-time monitoring allow consistent results across high-volume production lines.

Benefits for Coating and Finishing

Proper mechanical polishing enhances downstream treatments and product longevity.

Improved Adhesion and Uniformity

-

Smooth, defect-free surfaces allow electrophoretic coatings, electrostatic powders, or anodic oxidation to bond uniformly.

-

Minimizes risk of peeling, blistering, or uneven coloration.

Long-Term Durability

-

Polished surfaces combined with corrosion-resistant treatments extend product lifespan.

-

High surface brightness maintains aesthetic appeal even under harsh conditions.

KaiMeiDa’s High-Technology Polishing Solutions

At KaiMeiDa Aluminum, our advanced facilities and professional team ensure precision polishing for every aluminum profile:

-

12 advanced extrusion lines and multiple coating and transfer lines guarantee high-quality starting material.

-

Imported examination devices from Japan and Germany monitor surface roughness and brightness in real-time.

-

Specialized lines support oxidation, electro-coating, colored powder, sandblasting-electrophoretic, and wood grain transfer treatments.

-

Expertise in industrial, office, window, door, and glass curtain wall profiles ensures consistent surface quality across applications.

Our approach combines mechanical precision, process control, and surface treatment integration to achieve aluminum profiles that meet GB/T3190-96 chemical composition standards and deliver high brightness, wear resistance, and corrosion protection.

Conclusion

Reducing surface defects through mechanical polishing is critical for producing high-performance aluminum profiles. By employing stepwise abrasive techniques, optimized pressure and speed, and advanced monitoring systems, KaiMeiDa Aluminum ensures durable, aesthetically perfect, and technically reliable aluminum surfaces for industrial and architectural applications

http://www.jxkmdly.com

Jiangxi Kaimeida Aluminum Co., Ltd. -

-

AuthorPosts

- You must be logged in to reply to this topic.