- This topic is empty.

-

AuthorPosts

-

05/02/2026 at 10:03 #7132

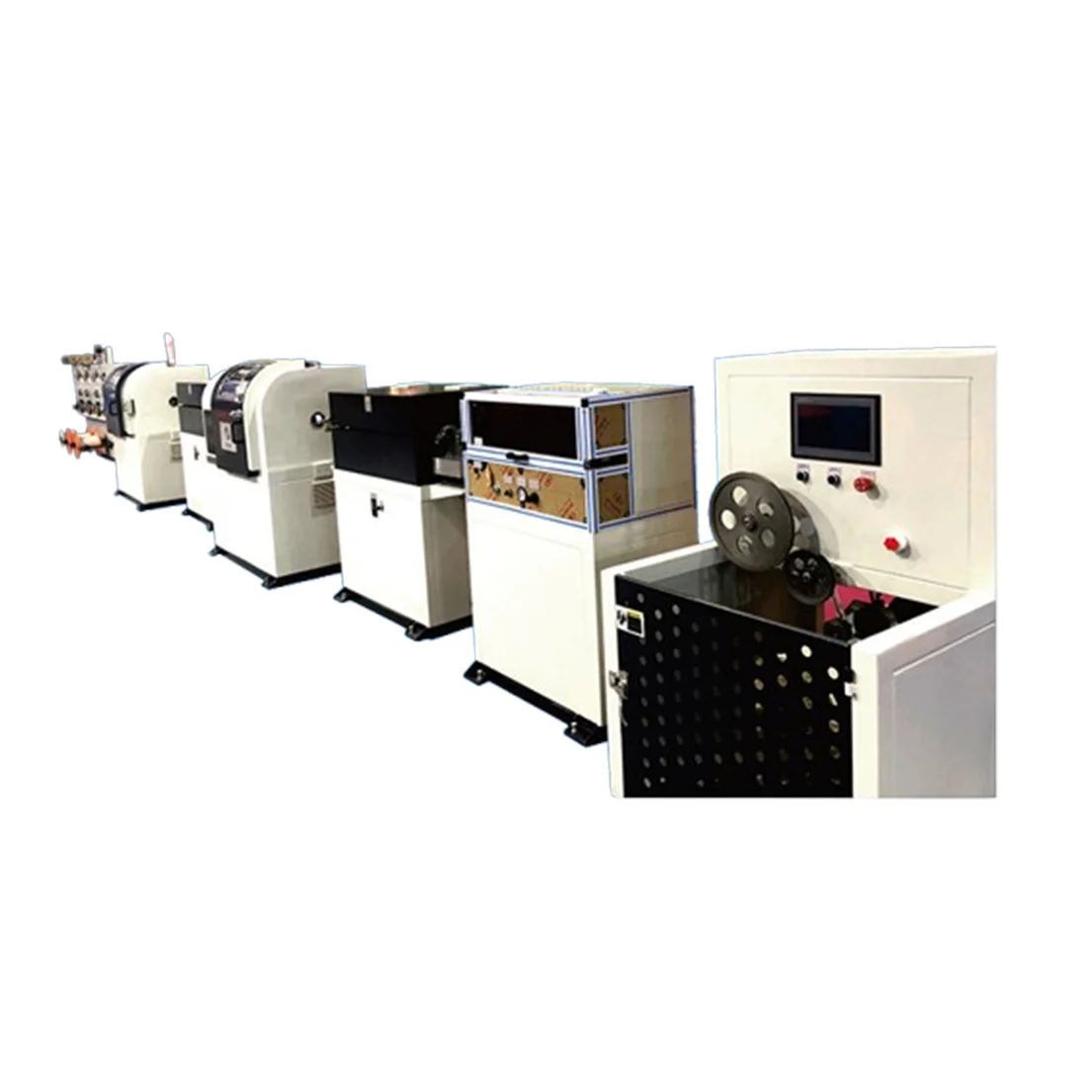

High-frequency cables such as HDMI, DP, SATA, and SAS demand precise construction, consistent shielding, and reliable signal integrity. Jinghan Machinery (Dongguan) Co., Ltd., with over 25 years of expertise in precision cable equipment, has developed a horizontal dual-layer tape wrapping system designed to transform cable manufacturing. By combining high-speed automation, dual-layer wrapping, and intelligent tension and pitch control, this system addresses the specific challenges faced by manufacturers producing complex, high-frequency cable structures.

Dual-Layer Wrapping for High-Frequency Cable Performance

The horizontal dual-layer tape wrapping system applies two tape layers simultaneously, providing:

-

Uniform shielding coverage: Ensures consistent impedance and reduces signal interference

-

Stable mechanical structure: Maintains conductor alignment and prevents deformation

-

Enhanced high-frequency performance: Critical for HDMI, DP, SATA, and SAS cables

By maintaining a precise overlap and consistent layer thickness, the system minimizes defects common in traditional single-layer wrapping processes, improving both electrical and mechanical performance.

Automated Tension and Pitch Control

Precise tape tension is essential for maintaining layer uniformity, especially at high production speeds. The horizontal dual-layer system integrates automated tension management and PLC-controlled pitch, offering:

-

Continuous tension adjustment from full to empty rolls

-

Stable tape forming points during acceleration and deceleration

-

Reduced operator dependency for consistent production quality

Benefits include:

-

High repeatability across production batches

-

Minimized material waste and rework

-

Uniform diameter and shielding density along the entire cable length

Axial Line Arrangement for Smooth Workflow

To optimize downstream operations, the system employs an axial line arrangement that ensures cables exit the wrapping head neatly and consistently. This design allows:

-

Easy integration with jacket extrusion, braiding, and take-up systems

-

Adjustable line width and spacing for different cable types

-

Efficient handling of multi-cable production lines

The orderly cable arrangement reduces handling errors and protects the structural integrity of high-frequency wires.

High-Speed Automation Enhancing Manufacturing Efficiency

The horizontal dual-layer design delivers high-speed automation advantages that directly impact production throughput:

-

Up to 2.5× higher output compared to traditional strap wrapping machines

-

Continuous dual-layer operation without frequent recalibration

-

Compatibility with twisted-pair and parallel wire constructions

-

Stable operation with various tape materials and cable geometries

By combining speed with precision, manufacturers can meet market demand without compromising cable quality.

Strategic Advantages for Cable Manufacturers

Implementing Jinghan Machinery’s horizontal dual-layer tape wrapping system provides:

-

Consistent product quality across HDMI, DP, SATA, and SAS cables

-

Reduced reliance on operator skill for precision wrapping

-

Flexible production lines for multiple cable types

-

Improved shielding performance and signal reliability

This system allows manufacturers to achieve operational efficiency, higher yield, and long-term competitiveness in high-frequency cable production.

FAQ: Horizontal Dual-Layer Tape Wrapping System

Q1. Can the system maintain precise layer overlap at high speeds?

Yes, PLC-based pitch control ensures consistent overlap throughout continuous operation.Q2. Does it require manual tension adjustment?

No, the system automatically regulates tape tension from full to empty rolls.Q3. Can it handle different cable structures?

Yes, it supports twisted-pair, parallel wires, and both single- and dual-layer center-wound tapes.Q4. What is the typical production yield for high-frequency cables?

Configured correctly, the system achieves nearly 100% pass rate for HDMI, DP, SATA, and SAS cables.Q5. How does it improve downstream processing?

The axial line arrangement ensures neat cable output, simplifying integration with extrusion, braiding, and take-up processes.Conclusion: Jinghan Machinery Leading Cable Manufacturing Transformation

Jinghan Machinery’s horizontal dual-layer tape wrapping system fundamentally transforms the production of HDMI, DP, SATA, and SAS cables. By integrating dual-layer wrapping, high-speed automation, and intelligent tension and pitch control, it enables manufacturers to produce high-frequency cables with exceptional structural integrity and performance consistency. With decades of innovation and global deployment, Jinghan Machinery continues to set the standard for advanced cable manufacturing equipment, helping clients achieve higher efficiency, reliability, and competitiveness.

http://www.jinhanmachinery.com

Jinghan Machinery (Dongguan) Co., Ltd. -

-

AuthorPosts

- You must be logged in to reply to this topic.