- This topic is empty.

-

AuthorPosts

-

09/09/2025 at 17:57 #6108

https://www.xinghuijm.com/Material-Selection-for-Customized-Tooling-Fixture-Test-Racks.html

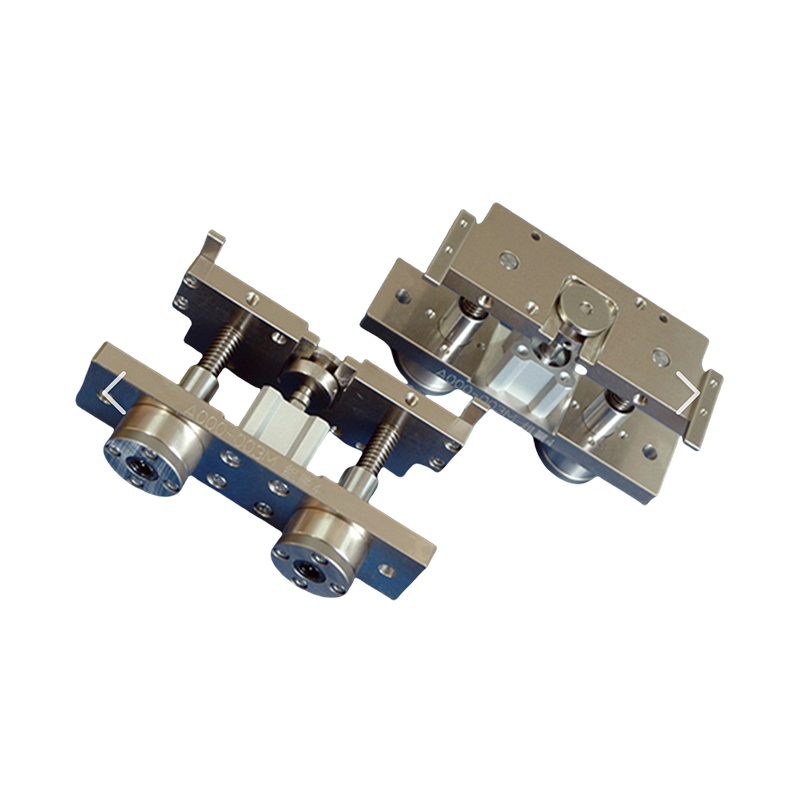

In the realm of precision testing and quality control, the backbone of reliable operations lies in the materials chosen for tooling fixture test racks. Shenzhen Star Precision Machinery Co., Ltd. excels at crafting customized tooling fixture test racks, and central to their performance and longevity is the careful selection of materials. Whether made of steel, aluminum, or advanced composite materials, each option offers unique benefits tailored to demanding testing environments.

1. Common Materials for Fixture Test Racks

Steel

-

Known for its exceptional tensile strength, steel offers a sturdy and long-lasting foundation—ideal for heavy-duty, high-load applications.

-

It resists deformation and surface wear, making it perfect for long-term, repetitive use.

Aluminum

-

Lightweight yet strong, aluminum contributes to improved operational agility and easier handling.

-

Its natural corrosion resistance and adaptability to treatments like anodizing enhance durability and aesthetic appeal.

Composite Materials

-

Modern composites offer a superior stiffness-to-weight ratio, combining lightness with structural resilience.

-

They perform exceptionally well in specialized applications where weight reduction or thermal stability are critical.

2. Why Material Selection Matters

The right material ensures that the fixture test rack delivers consistent performance across its service life:

-

Structural Integrity: Robust materials like steel prevent growth or failure under stress, maintaining alignment and stability during testing.

-

Longevity: Materials resistant to wear, rust, or environmental degradation extend the operational lifespan of fixtures.

-

Performance: Lightweight yet durable materials such as aluminum and composites ease handling, reduce setup time, and enhance efficiency.

-

Application Fit: Composites may offer unique benefits such as vibration damping or reduced thermal expansion—essential for high-precision tasks.

3. Why Shenzhen Star is Your Trusted Partner

Shenzhen Star Precision Machinery Co., Ltd. understands that precision begins with materials. Here’s how their expertise benefits your customized tooling fixture test racks:

-

Customized Material Selection

Products are engineered using appropriate materials—be it steel for ultimate strength, aluminum for mobility and corrosion resistance, or composites for specialized needs. -

High-Precision Fabrication

Whether you require light racks with tight machining tolerances or heavy-duty frameworks, their manufacturing processes ensure precise dimensions and consistent quality. -

Tailored Solutions for Every Application

Shenzhen Star collaborates closely with clients to match material characteristics with production environments and testing requirements—whether it’s reducing operator fatigue with lighter aluminum fixtures or maximizing longevity in harsh settings with coated steel.

Choosing the right material for customized tooling fixture test racks is more than a technical decision—it’s a strategic investment in efficiency, reliability, and return on equipment uptime. Shenzhen Star Precision Machinery Co., Ltd. stands out for its deep material expertise and tailored approach, delivering fixture racks that perform precisely the way you need them to, today and for the long term.

https://www.xinghuijm.com/Material-Selection-for-Customized-Tooling-Fixture-Test-Racks.html

Shenzhen Star Precision Machinery Co., Ltd. -

-

AuthorPosts

- You must be logged in to reply to this topic.